Chok-Coated Koffee Beans

Chok-Coated Koffee Beans

Regular price

$18.90 AUD

Regular price

Sale price

$18.90 AUD

Unit price

per

Tax included.

Bite into the ‘velvety’ taste of Yahava’s chocolate-coated Peaberries!

We have taken fresh roasted, almost round Peaberry coffee beans and coated them with silky smooth Belgian chocolate. Bite through the creamy coating of one of the world’s finest chocolates and into a crunchy roasted Yahava Koffee Bean.

We start with a very special coffee bean

How we coat our beans

A high gloss finish

Collapsible content

How Many Chok-Coated Koffee Beans Are Inside?

How Much Does Shipping Cost?

Where Do You Ship?

Can I Use A Yahava Online Gift Card To Checkout My Purchase?

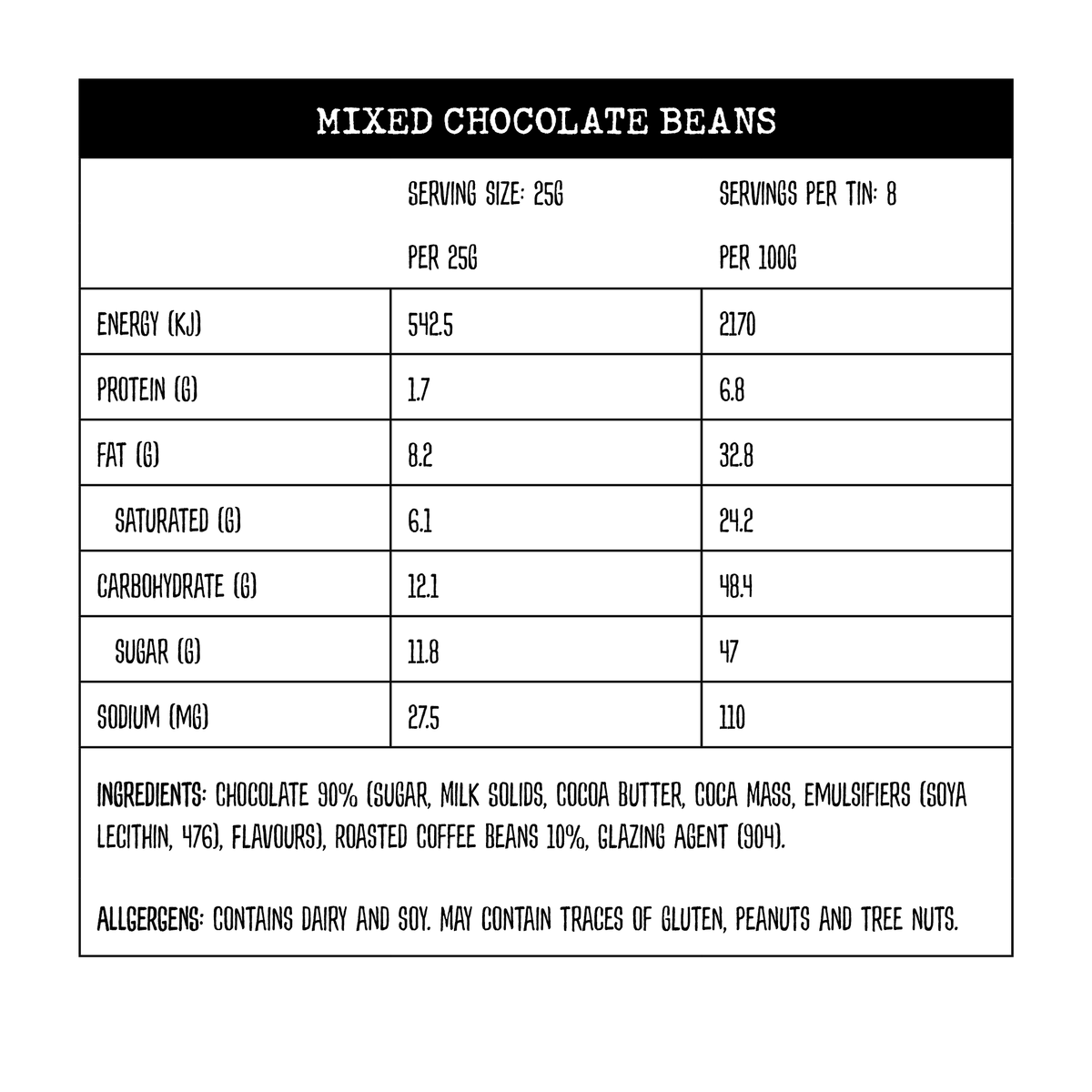

Ingredients & Nutritional Information